Exchangers are possibly one of the most important and widely used pieces of equipment found at various industry sites. Regardless of the industry in question, it will possibly require some type of temperature regulation and that is where exchangers come in.

They can be used for heating or cooling, but, in the industrial sector, especially at refineries and plants, they are often used for cooling. In this article, you will be able to read what are industrial heat exchangers, why they are needed, how they work, and their classification. Let’s start with the basics:

What is Industrial Heat Exchangers?

As the name implies, industrial heat exchangers are pieces of equipment which are designed to either exchange or transfer heat from one medium to another. The heat exchange might be the main purpose of heating up elements or cooling the elements down.

In the industrial sector, cooling tends to be used more often to prevent volatile substances or equipment from overheating. There are different types of heat exchangers, each with its own benefits, yet each of them is tailored to suit different industries and purposes.

Why are Heat Exchangers Needed?

As previously mentioned, this equipment has a wide range of industrial applications. They are used as parts of air conditioning and cooling systems, or of heating systems. A lot of industrial processes need a specific degree of heat to function – however, a lot of precautions are made to stop these processes from becoming too hot.

These heat exchangers are needed to keep chemicals, machinery, gas, water, and other substances within a safe operating temperature. They can also be used for capturing and transferring steam or heat exhaust that is released as a byproduct of an operation or process, hence, the heat or steam can be used elsewhere, so you can increase efficiency, as well as save money for your facility.

How Do They Work?

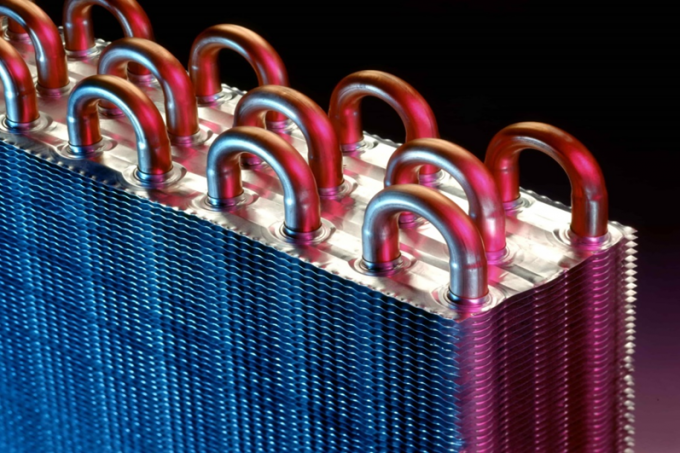

Since there are different types of heat exchangers, they all work in different ways, use different arrangements, equipment, and features. However, one thing that they all have in common is that they all work to directly or indirectly expose a warmer medium to a cooler one, hence, they exchange heat.

This is usually done by using tubes housed in a casing. Heat exchanger fans, belts, condensers, additional tubes and lines, coolants, and other components work to increase the cooling and heating efficiency or improve flow. If you want to read more about these heat exchangers, visit this website.

The Classification of Heat Exchangers

They are usually classified by one of the four metrics listed below:

1. The nature of the heat exchange processes

2. The physical condition of the fluid

3. The exchanger’s flow arrangement

4. The construction and design of the exchanger

Keep in mind that heat exchangers do need proper servicing and maintenance. The maintenance and servicing will vary based on the type you have, as well as the construction and design of the machine.

Conclusion

These heat exchangers will not only help you with the processes in your facility, but they can also save you a lot of money, protect the environment, and keep your processes going. Hence, if you still did not implement this technology into your facility, do not waste any more time and start searching for a heat exchanger that will fit your facility’s needs.