Rotational molding is a unique manufacturing process that competes mainly with injection molding. Still, rotational molding offers many advantages for startups and new businesses, especially those who need to produce smaller product batches, prototypes or test new products before launching mass production.

In this article, we’ll cover rotational molding as a main choice. Companies like the Canadian Rotoplast Inc. leverage this technique for many specific benefits. Knowing that it’s an ideal choice for limited batches of products. Additionally, rotational molding is great for complex shapes and larger parts that may not be possible using injection molding.

Tips and Considerations for Success

Let’s now cover some of the most essential aspects of using rotational molding for your business. That way, you can easily estimate if your business will be successful and the scope of products you need to launch for more convenient production.

Initially, you need to do these things:

Research the Target Market

By focusing on a specific niche, you can find something you’re good at. Don’t try to compete with the industry giants, but focus on a niche that may bring enough profit for you. By discovering a market part where you can place your rotational molding products and offer a unique advantage without competing with the already established brands, you ensure a market position and relevance in the long term.

Business Planning and Investment

It’s not a cheap thing to invest in rotational molding machines. So, before doing that, make sure you develop a detailed business plan. Research the target market, product range, production capacity, and financial expectations and projections. After that, you’re ready to establish a marketing strategy to help you promote the service.

Additionally, you need to secure the funding. Try to estimate the loans, capital, investment, and budgeting before jumping into new businesses.

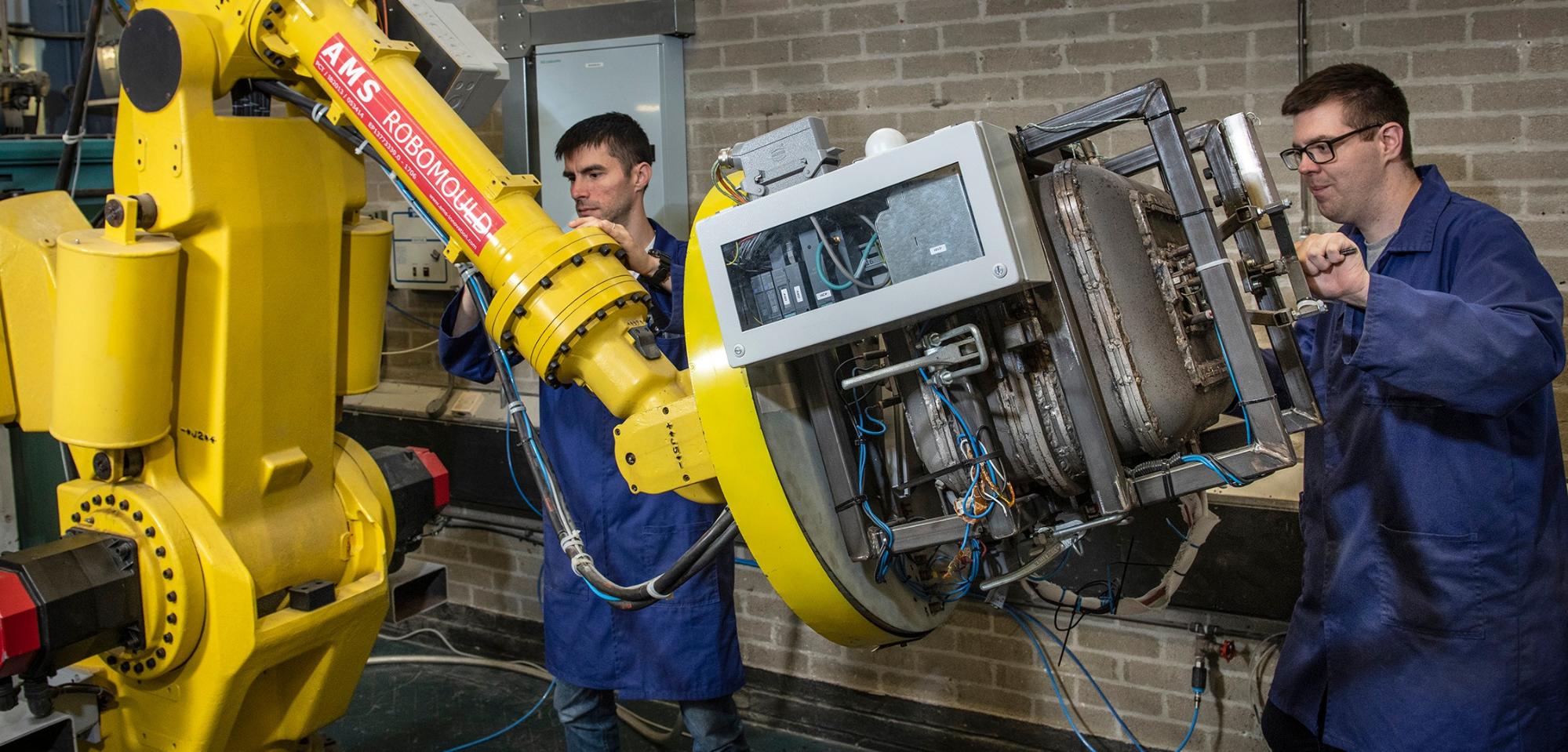

Production Setup and Equipment

It’s time to invest in machines so you can start with your business. We suggest you initially invest in a smaller number of machines suitable for your production volume. Consider factors like rotation speed, heating capacity, and cooling systems.

Also, you must invest in quality materials like polyethylene and nylon. Find suppliers and build relationships with them so you can always have what to work with. Quality materials will ensure you always provide quality products to your clients while creating opportunities to grow more and be recognizable on the market.

Operations and Quality Control

Before going anywhere further, you need to implement an efficient production process. It would be great to streamline material handling, mold preparation, rotation cycles, and even cooling stages.

That way, you can gain control over quality to always provide consistent and unified products. Everything should meet the industry standards so you can stay ahead of your competition.

Marketing and Sales

In rotational molding, it’s not enough just to have quality products that satisfy the market demand. You also need to find a way to market your business and showcase your expertise. That way, you can attract the right audience, increase sales, and attract even more potential customers who will use your services. Position yourself as a market leader in your niche, and even learn how to produce complex shapes to seal that position.

As a result, you’re able to develop stronger customer relationships and build trust and loyalty. Using excellent communication, responsive service, and on-time delivery, your customers will be satisfied with your offer and probably use your services over and over again.

Navigating Challenges and Growth

The rotational molding industry always relies on trends but also on existing foundations. To stay in the market, you’ll have to learn more about new materials, methods, and market demands.

If you have employees, invest in their training so they can have the necessary skills to operate and maintain the equipment. Also, don’t be afraid of innovation. Embrace it so you can improve the product range and efficiency.

Build a Strong Team

We hope that at some point, you’ll have to work with a whole team behind you. They should be skilled in rotational molding, mold design, and quality control. So, make sure you find the right people to extend your business.

Encourage teamwork, especially when you have more creative products to work on. Surely, you can start small, so you won’t need to hire people just to fire them a few months later. Instead, focus on consistent growth and hire new employees when there is a realistic need for that.

As a result, we are sure you’ll maintain a great product development process and customer satisfaction at the highest level.

Embrace Sustainability

It’s not hard to maintain an eco-friendly and sustainable business these days. You can explore recyclable options or even use recycled materials to align your offer with the customer demand for sustainable products.

Also, you can use energy-efficient practices and optimize the overall rotational molding processes. We suggest you develop a recycling program and encourage the clients to return used products, minimize waste, and promote circular production.

Conclusion

You can’t expect instant success in the rotational molding industry. You must learn new trends and methods, adapt to the industry switches, and embrace innovation to ensure long-term success in this dynamic industry that requires lifelong learning all the time.

Also, you need to stay flexible even when focused on niche-specific products. So, plan the investments in equipment, be careful with the budgeting, and use proven marketing strategies to build stronger customer and partner relationships. That way, your rotational molding business can stay ahead of the curve of this growing industry.

So, focus on your business plan, quality production, and even more quality customer service. We are sure you’ll easily pave the way to success while maintaining a sustainable business that meets all the industry standards and satisfies the needs of each customer!