If you’re running a business, you probably want to save money in all areas of your company. Did you know that you can save money by analyzing your costs related to packaging your product? You might be surprised how much money you save just by changing some packaging decisions.

Here ways for you to save money just by changing your product packaging:

1. Check Your Product Details

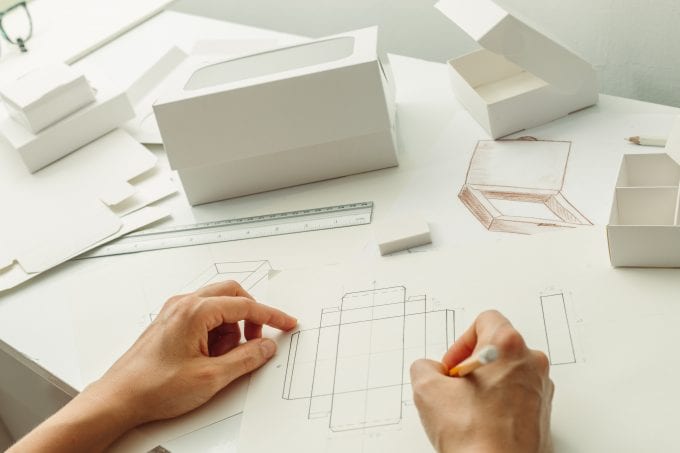

It may seem childish to tell a business owner to ‘check your product details,’ but it’s true. Being vaguely oriented with how big your product is or how heavy it is may be costing you quite a bit without you realizing it. Thus, you need to know your product well before you can place an order for its packaging.

Once you’re aware of the details about your product, you can place an order for the appropriate packaging with a reputable packaging supplier, such as Stanley Packaging.

2. Check the Use and Cost of Each Type of Packaging

If you already know the details about your product, you may try to learn how each type of available packaging works and how much it’ll cost you to use that packaging. You might discover that you’ve been using packaging that’s too big for your product, which means that you’re spending more just to use that packaging.

Essentially, you can simply save money by downgrading your packaging choice to the bare essentials.

3. Find Other Uses for Your Packaging Inventory

One problem that you might encounter when you downgrade your choice of packaging is that you may have a lot of the previous type of packaging in your storage area. Since you won’t be able to use that kind of packaging anymore, and you need the extra space for other business uses, it’s best to seek ways to use that up as soon as possible.

For instance, if your office is near the office of a publishing company, you may want to ask them if they want to buy your excess packaging, such as bubble wrap, at a discounted price. The publishing company can use the packaging for shipping their books and other publications to vendors all over the country. They’ll probably be pleased to acquire good quality packaging at a lower price.

This way, you were able to eliminate inventory plus you regained most of the capital you invested in acquiring the packaging. Most importantly, you did a good deed for another company, too.

4. Avoid Buying in Bulk

If you’ve ever bought packaging through a bulk order, you’re probably aware that you can save quite a bit per order. However, do you really need that much? It may be more practical to buy just enough for a particular buying season. This way, you won’t have much packaging inventory left after that sales season and you didn’t invest too many resources to buy it in the first place.

These are all positives so you may notice that you’re getting better at rationalizing purchases, which translates to big savings for the company. Those savings can then be used for other business purposes, such as marketing your product with better packaging options.

5. Listen to Customer Feedback

You might be amazed at how many of your users are actually environmentally-conscious to care about how much packaging their shipment comes in. If you don’t have a customer feedback system, it may be time to develop one for your company. This way, you can appease the needs of these environmentally-conscious customers, allowing your company to be helpful to the environment as you’ll no longer use too much packaging that’ll just wind up in the landfill or the ocean

Ask your customers if they have any suggestions on how you can better use packaging to ship their goods. Also, ask your staff if they’ve been hearing anything from their interaction with customers. This customer feedback will help you avoid a trial-and-error system, which will cost much more in the long run.

6. Research About Government Regulations

Since the government may have regulations in place that determine product safety–and everyone knows that packaging will help protect their products en route to their destination–it’s important to be aware of the rules set by the government in your location.

These regulations will make it easier for manufacturers and vendors to send out and receive goods. End users will be grateful as well since they’ll be able to use their products that have arrived at their homes or offices in perfect condition.

7. Don’t Be Afraid to Upgrade If Necessary

Although it may seem that you’re always being asked to downgrade or reduce your use of packaging, there are definitely times when you must upgrade. How so? Remember that you’re using packaging so that end-users will receive products that are in pristine condition. If you downgrade your use of packaging, will your products arrive at their destination intact and without any damage whatsoever? Or, are you taking a big risk that can blow up in your face business-wise?

If you believe that your business would stand to lose money if you reduced packaging, let the current rules about its use stay by your company. Then, look for alternatives that won’t cost much, are environmentally-friendly, and are readily available when your business needs it. That way, end-users will not have to send you angry messages just to complain about their damaged purchases that’ll need replacing with new ones.

Final Takeaway

In these difficult times, saving money is on the to-do list of any business owner or manager because there’s more competition for consumer dollars now. If you want to save money, consider changing your packaging if it’s too wasteful or just doesn’t do the job right for your company.

You may inspect each product to see if there are ways to cut back on the packaging due to the size or special characteristics of the product. But don’t cut back on the packaging if you would be putting product safety at risk. Customers will only pay for products that arrive intact.

If necessary, set in place a customer feedback system so that you and your staff will learn from the experiences of your preferred customers easily in real-time.