If 5S is a new term to you, it refers to a clean, safe, uncluttered, and highly organized methodology business owners use in a workplace. It’s aimed at reducing wastage while leveling up productivity. Furthermore, you can deploy this model to establish a quality work environment mentally and physically.

In essence, if you’re looking forward to improving the efficiency of your business-to-business (B2B) or business-to-customer (B2C) enterprise, the miracle that you need might be the 5S metric.

The advantage of the 5S model is that it can be used in both manufacturing and office environments, whether it’s in your small or large company. To know more concerning 5S lean, especially on its implementation, you may click here.

The Genesis Of The 5S

It’s generally accepted that 5S lean manufacturing is a model developed in Japan, with the intention of transforming raw materials into revenue for businesses, while giving real value to customers. It’s loved due to its capacity to offer efficiency, as well as save time on the part of businesses and customers.

The developers of 5S purposed to evaluate and overhaul manufacturing facilities, processes, and offices of a company to ensure that every day is productive for easy achievement of company goals.

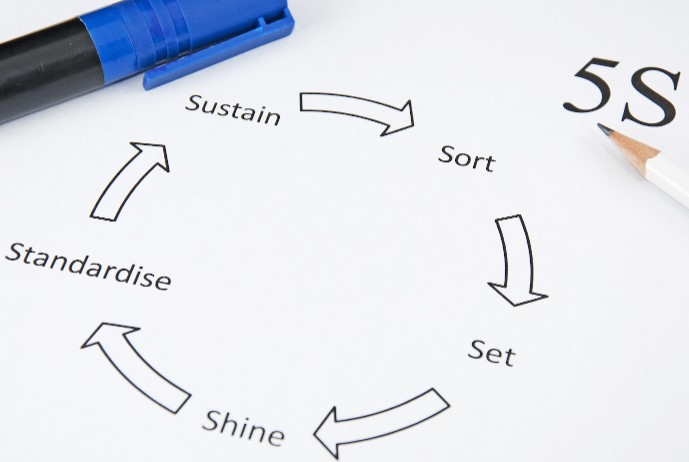

A Brief On The 5S Formula

For all businesses that have instituted the 5S model, it, universally, has five areas of focus. However, for the sake of customizing the model to fit any business or office, the approach might differ from one company to another. That said, a 5S for a manufacturing business might appear different from a shipping warehouse even though they’re using the 5S matrix.

The key areas of 5S focus are

Sort: The purpose of sorting is to distinguish between items that are and aren’t needed for use at work. Items that aren’t needed are removed. Your goal for sorting is to declutter every place, such as the workbenches, closets, bookshelves, desk and file drawers, and computer files.

Set In Order (Straighten): Here, you’re supposed to organize all tools and items in their areas of storage. It might be in specific shelves, labeled bins, or wall spaces.

Shine: This aspect helps keep your sorted and straitened areas clean and neat. As a result, you ought to keep your surfaces dust-free and tidy. Additionally, this standard ought to be maintained every day, with a commitment from your team members.

Standardize: Here, you should aim to create a consistency of the set systems for the smooth running of a workplace. As a result, 5S should be owned by everyone, the management, and employees.

Sustain: At this level, you assign responsibilities to different people whose work is to maintain instituted processes. Besides assigning, the processes ought to be regularly evaluated, updated, improved, and revised.

Key Benefits Of 5S Workplace Implementation

The returns on investment (ROI) of 5S are guaranteed if it’s implemented successfully, in which case you remove unwanted items, tidy up spaces, reorganize, develop procedures, and create a culture of good discipline.

Here are the benefits that you get from 5S implementation:

Better Productivity

There’s no single organization that doesn’t aim at improved productivity, which, in turn, improves business revenues. It’s generally believed that the effective institution of 5S lean manufacturing processes can level up your business’s productivity.

However, to achieve this, you need to, first, do away with unnecessary tools and maximize your workplace resources, resulting in minimal time wastage.

Moreover, because of the structured nature of 5S, tools and items are stored to make them quickly accessible for use. This ensures that involved parties know where to get what they need in the shortest time possible without derailing the production process.

Improved Safety

Better safety is a major advantage of the 5S model. Mainly, improved safety will result from a clean workspace, particularly in manufacturing, which significantly reduces the chances of injury incidents. Good workplace organization ensures that every item is kept where it’s supposed to be, thus, sustaining the safety of your employees.

Things such as sharp objects lying on the ground threaten an individual who may accidentally fall on them. In addition, unattended chemicals raise the chances of falls and slips. Therefore, you should religiously adhere to cleaning procedures to significantly lower unintended mishaps through the instituted standards.

Moreover, encourage your workers to minimize movement in a workplace, particularly where there are potential injury sources. Regular sensitization of your employees to be cautious, in return, helps them become trailblazers of safety in your organization.

Reduction Of Wastage

Adhering to 5S has the potential to minimize the loss and damage of tools in your business. To achieve this, ensure you have proper labeling procedures to facilitate your workers to track all items in the workplace. With this, you can easily spot damaged items and quickly replace them, including equipment that might be lost.

In addition, when tools are stored in the right places, you can reduce the chances of destruction. For instance, liquid chemicals or other fluid substances should be placed in areas that are free from sharp objects. This is because, in case a container falls, it can be punched, making the chemical drain from the container.

Moreover, items that need to be refrigerated shouldn’t be exposed to heat to ensure that their longevity is sustained. In summary, items that have storage instructions should be stored as recommended.

Worker Commitment

When implementing the 5S lean model, ensure that you involve your workers fully. In the long run, it’ll create a sense of ownership and responsibility. Furthermore, encourage them to provide ideas that help in streamlining emerging weaknesses of the procedures. In addition, ask them to be fully involved in the maintenance works.

Efficiency

Due to the thought-out nature of 5S, it helps eliminate bottlenecks in the workplace. Besides, you also gain from fast workflow due to better use of resources. In addition, you’re guaranteed the improvement of the quality of your products and services. Furthermore, reduced time wastage helps ensure that products are released from production within the set time, thus, helping in reducing production costs.

Bigger Storage Space

Sometimes, a workplace might seem full not because there’s much to house, but due to a clutter of unnecessary items. However, the moment you declutter items that aren’t needed, you’re able to create more space to store needed items.

Wrapping Up

Even though the 5S model has been in use for decades now, it’s stood the test of time. Business owners who’ve implemented it have testified of the tremendous gains they received. If you’re still in the indecision stage concerning 5S lean manufacturing, this article is a masterpiece of the benefits that you’re bound to gain from its implementation.