The overall usage of plastics has gone higher these days. Earlier, there was not that much of a need to recycle these products. But now, it has become a significant step towards reducing pollution. New and advanced technologies are available to transform recycled plastic. If you are eager to know about it, you have come to the right place. In this article, we will discuss the overall process in detail.

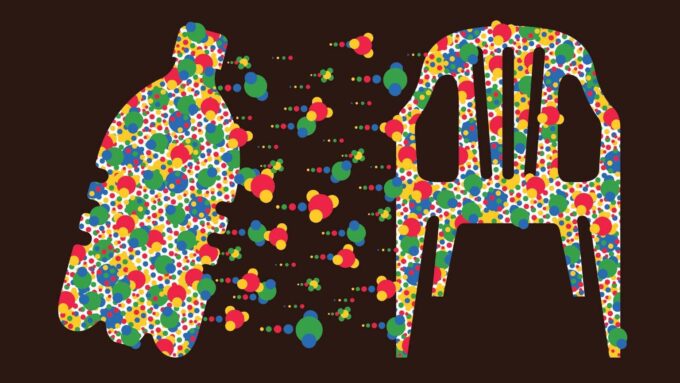

Recycling plastic is one of the toughest tasks. But now, there are diverse techniques to do it. With the help of these technologies, different materials are manufactured. Nowadays, recycled plastic furniture is trending and many people are considering buying it. It is indeed astonishing to know that plastic can be converted into furniture items. The credit goes to the new and advanced technologies.

The procedure of transforming plastic into something else seems complex. Still, many industries create products using this particular process. Let’s now get into the details of it.

What Are The Steps Involved In Transforming Recycled Plastic?

Transforming recycled plastic into something else requires a lot of effort and time. There are some specific steps that the process follows and without them, the results won’t be that good.

Gathering The Plastic

The first thing that every industry does is gather the plastic. You can easily find a source from which these plastics come. That is how you can proceed to make some decisions.

Gathering the plastic involves collaborating with diverse groups to get good stuff. The more you focus on collaboration, the better outcome you will experience. Many industries work with companies to make the collection task easygoing.

Sorting

The next step of the process is sorting. Under this step, the machine sorts out the items that are necessary for further processing. This division is based on a variety of things like thickness, texture, color, and more.

Sorting is a significant step as it paves the way to the actual procedure. Now, new technology used in machines has made this step quicker and better. Industries always consider using these machines as they are pretty powerful.

Cleaning Or Washing

After sorting, plastics then go through the cleaning process. This step plays a huge role as it helps eradicate the impurities that might hamper recycling. Impurities can be of several types. For instance, there must be product labels, dirt, remaining food, etc. These directly negatively impact the recycling process. So, industries use high-technology machines to do this step perfectly.

Industries always ensure that cleaning or washing the plastic is done carefully. It further makes recycling much faster.

Shredding

The next step in the transformation process is shredding. Shredding machines break down plastics into smaller pieces so that these can be used to make products. It also helps remove any impurities that are still there in the plastics. And that is how they move to the next step. Small pieces of plastic are also used as raw material. Many industries buy them from recycling factories.

Sometimes, the impurities are not just dirt or food remains, but also metal. While shredding, the metallic particles are detected by the machine. They get stuck in the magnet integrated into the machine. Once everything is sorted, the recycling process moves further ahead.

Separation And Identification

Plastics are of different types and not all of them can be utilized to manufacture products. Therefore, the separation and identification step is crucial. It helps identify the plastics according to their properties, especially their density, and separate them accordingly.

Floating the pieces in a water container is the first step to check the density. Then they are separated by doing air classification. It measures the overall thickness of the plastic which is pretty helpful in the manufacturing process.

Manufacturing

The last step of the recycling procedure is manufacturing. The plastic pieces are converted into diverse products, depending upon the type of plastic. Industries choose the same according to their product requirements.

The plastic pieces can be transformed into diverse products like furniture, containers, bottles, and more. All these products are manufactured in their respective industries. The product quality is not just on the plastic but also on how it is manufactured.

Different Types Of Technology For Plastic Recycling

Plastic recycling is done in a variety of ways. Many technologies help improve the overall process of transforming plastic into a finished product.

Some significant technologies for recycling plastic are-

Chemical Recycling

Chemical recycling is one of the most sustainable techniques for breaking down the plastic. Under this process, the plastic is converted into its previous original form. It is also known as virgin equivalent plastic. That is how industries use the original form in finished products.

Dissolution Recycling

Dissolution recycling is an important recycling technology that many industries prefer over others. The overall process is based on separating the polymers from the plastic. After that, they get dissolved in the solvent. As a result, they end up coming back to their purest form. This form is then converted to diverse products.

Mechanical Recycling

The most common process of plastic recycling is through machines. For every step, machines are used to break down the plastic. The result is the small pieces. These are then utilized in manufacturing different products. It is also a sustainable procedure that helps reduce overall pollution.

Organic Recycling

It is another sustainable type of recycling where the plastics are converted to organic waste through microbiological treatment. Organic waste is used in agriculture and it enhances crop production.

Monomer Recycling

This process breaks down the long polymer molecules into monomer building blocks. These building blocks are then used for producing virgin plastic items. The overall procedure of monomer recycling is quick and convenient. Therefore, numerous industries are in awe of this technology.

Final Thoughts

Plastic can be recycled in several ways. The technologies used in recycling plastic produce different outcomes. Industries must consider researching every method to discover the most suitable one. Also, every method has its pros and cons. So it is necessary to comprehend them in detail.