Companies are continuously seeking ways to enhance productivity, reduce errors, and improve quality. Robotic vision systems (RVS) are at the forefront of this transformation, providing manufacturers with the ability to automate tasks that require high precision and flexibility.

By integrating RVS into manufacturing processes, businesses can not only boost their output but also enhance their quality control, all while minimizing costs.

The Role of Robotic Vision Systems in Manufacturing

Robotic vision systems play a crucial role in modern manufacturing, especially in tasks that demand high precision and consistency. One of the most significant ways they improve productivity is by enhancing automation.

For example, robots equipped with vision systems can perform intricate assembly tasks or inspect products for defects without the need for human oversight, reducing the risk of error and increasing speed.

Additionally, these systems improve workflow efficiency by ensuring that robots can quickly adapt to different products and production lines. Unlike traditional automation tools, which may require reprogramming or downtime when switching between tasks, robotic vision systems can identify parts and adapt their movements in real time.

Key Advantages of Using Robotic Vision Systems

Robotic vision systems offer several key advantages that directly impact productivity in manufacturing:

Increased Efficiency

By automating tasks such as assembly and quality inspection, robotic vision systems help streamline operations. These systems can perform repetitive tasks faster than humans, allowing manufacturers to increase throughput without sacrificing quality. Whether it’s sorting products on an assembly line or inspecting each part for defects, RVS ensures that processes run smoothly and without delays.

Enhanced Precision

Precision is critical in manufacturing, particularly in industries like electronics, automotive, and aerospace. Robotic vision systems enable robots to perform tasks with micron-level accuracy, reducing the risk of errors and improving product quality. Whether it’s placing tiny components on a circuit board or aligning complex parts in an assembly, RVS ensures that every task is performed to the exact specifications.

Cost Reduction

Robotic vision systems help reduce manufacturing costs in several ways. They minimize human errors, which can lead to costly mistakes, rework, or scrap. By reducing the need for manual labor in tasks such as inspection or assembly, companies can allocate resources more efficiently. Furthermore, the increased speed and precision of these systems translate into faster production cycles, ultimately lowering operational costs.

Flexibility and Scalability

Robotic vision systems are highly adaptable, allowing manufacturers to quickly change production lines or switch between different products. This flexibility ensures that companies can respond quickly to changing customer demands or adjust to new product specifications without the need for extensive reprogramming.

Applications of Robotic Vision Systems in Manufacturing

Robotic vision systems are revolutionizing various manufacturing applications, including:

Assembly Line Automation

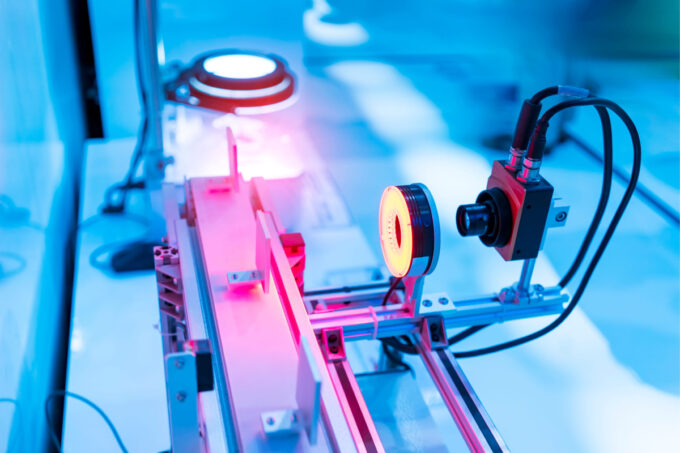

One of the most common applications for robotic vision systems is in assembly line automation. Robots equipped with vision systems can identify parts, determine orientation, and place them in the correct position on a production line. This enables faster and more accurate assembly, especially in industries like automotive manufacturing, where precision is essential.

Quality Control and Inspection

Robotic vision systems are invaluable for quality control. They can automatically detect defects, misalignments, or surface anomalies that would be difficult or impossible for the human eye to spot. Whether it’s identifying scratches on a metal surface or verifying the dimensions of a part, RVS ensures that only high-quality products leave the factory floor.

Packaging and Sorting

In industries like food and beverage, packaging, and pharmaceuticals, robotic vision systems are used to sort products and package them efficiently. These systems can inspect each item for size, shape, and weight, ensuring that only correctly packaged products move forward in the process.

Collaborative Robots (Cobots)

Cobots are robots that work alongside human operators to assist in tasks without fully replacing them. With integrated vision systems, cobots can identify objects, adjust their movements based on visual input, and collaborate with humans in real time. This increases productivity while ensuring the safety and well-being of workers.

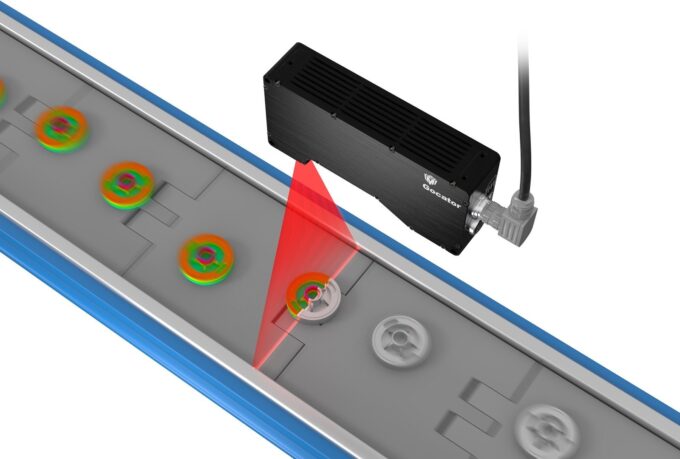

3D Laser Line Profile Sensors: Enhancing Robotic Vision

While traditional 2D vision systems are powerful, they are limited in their ability to accurately capture complex shapes and surface variations. This is where 3D laser line profile sensors come into play.

These sensors use laser lines to scan an object and create a three-dimensional profile of its surface. They are particularly effective for measuring the geometry of irregular objects and detecting subtle surface defects.

The high precision of 3D laser line profile sensors makes them ideal for quality control and inspection tasks. For example, these sensors can measure the shape of a machined part to ensure that it conforms to design specifications. They can also detect surface defects such as cracks, dents, or warping, which would be difficult to identify using traditional 2D vision systems.

3D laser line profile sensors complement traditional robotic vision systems by adding depth perception and dimensional analysis to the robots’ capabilities. This integration allows robots to perform more complex tasks, such as precise part alignment, assembly, and inspection, with a higher degree of accuracy.

For instance, a robot equipped with a 3D laser sensor and a standard camera can not only locate parts on a production line but also measure their dimensions and check for defects before assembly.

Conclusion

Robotic vision systems are rapidly transforming manufacturing by improving productivity, accuracy, and cost efficiency. With advanced technologies like Gocator 3D laser line profile sensors, manufacturers can achieve unprecedented levels of precision and automation.

As these systems continue to evolve, their ability to optimize manufacturing processes and enhance product quality will only become more powerful. For businesses seeking to stay competitive in the global market, investing in robotic vision technology is no longer a luxury—it’s a necessity.