The landscape of modern industries is undergoing a significant transformation, propelled by the relentless march of technological advancements and the ever-increasing demands for efficiency, sustainability, and customization. At the heart of this transformation lies a range of cutting-edge manufacturing solutions, each poised to redefine the paradigms of production, design, and supply chain management. These innovations are not merely incremental improvements but are foundational shifts that promise to usher in a new era of industrial prowess and productivity.

The Digital Fabric of Industry 4.0

The cornerstone of contemporary manufacturing solutions is the integration of digital technologies with traditional industrial practices, a fusion known as Industry 4.0. This integration is characterized by smart factories where cyber-physical systems monitor the physical processes of the factory and make decentralized decisions.

The digital fabric of Industry 4.0 is woven with the threads of the Internet of Things (IoT), big data analytics, and cloud computing, creating a seamless network of machines, systems, and people. This interconnectedness enables real-time communication and collaboration across entire manufacturing ecosystems, leading to unprecedented levels of efficiency and agility.

The Power of Additive Manufacturing

Additive manufacturing, more commonly known as 3D printing, stands as a beacon of innovation in the realm of manufacturing. Unlike traditional subtractive manufacturing, which carves out products from larger blocks of material, additive manufacturing builds objects layer by layer, offering a radical departure from conventional production methods.

This approach not only minimizes waste but also opens up possibilities for complex geometries and structures that were previously unthinkable. From aerospace components to custom medical implants, additive manufacturing is paving the way for tailored solutions and rapid prototyping, transforming the very essence of product development and manufacturing.

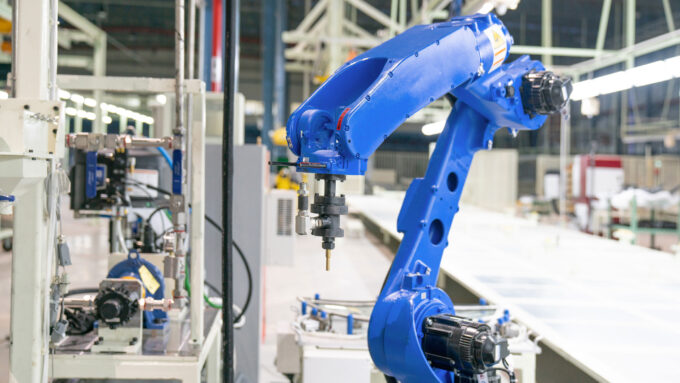

The Precision of Advanced Robotics

The adoption of advanced robotics in manufacturing is not merely an evolution; it’s a revolution. Modern industrial robots are endowed with precision, flexibility, and intelligence, far surpassing their predecessors in capability and performance. Equipped with sophisticated sensors and powered by artificial intelligence, these robots can perform a myriad of tasks, from delicate assembly operations to heavy lifting and hazardous materials handling. The integration of robotics not only enhances productivity and safety but also redefines labor roles, leading to a more skilled and adaptable workforce.

The Insights of Big Data Analytics

In the vast ocean of data generated by modern manufacturing processes, big data analytics serves as the compass that guides decision-making. By harnessing the power of advanced algorithms and machine learning, industries can uncover patterns, predict trends, and optimize operations in ways that were previously beyond reach. This analytical prowess extends across the supply chain, from forecasting demand and managing inventory to ensuring quality control and minimizing downtime. The insights gleaned from big data analytics are a valuable resource for strategic planning and continuous improvement.

Sustainable Manufacturing Practices

As environmental concerns take center stage globally, sustainable manufacturing practices have become a crucial aspect of modern industries. This involves the adoption of green technologies, efficient use of resources, and the minimization of waste and emissions. Renewable energy sources, such as solar and wind, are increasingly powering manufacturing facilities, while circular economy principles are being integrated into production processes. Sustainable manufacturing is not just an ethical imperative but also a strategic approach that can lead to cost savings and a stronger brand reputation.

Customization at Scale

The era of mass production is giving way to a new paradigm of mass customization, fueled by advancements in manufacturing technologies and changing consumer expectations. Today’s consumers seek products that cater to their specific needs and preferences, and modern manufacturing solutions are rising to the challenge. Technologies like additive manufacturing and flexible robotics enable the production of customized products at a scale and speed that rival traditional mass production methods. This shift towards personalization is transforming supply chains and business models, making customization the new norm.

The Integration of Augmented and Virtual Reality

Augmented Reality (AR) and Virtual Reality (VR) are transcending their origins in the gaming world to become powerful tools in manufacturing. These technologies offer immersive experiences that can enhance design, training, and maintenance processes. For instance, AR can overlay digital information onto physical objects, aiding in complex assembly tasks or maintenance procedures. VR, on the other hand, can create detailed simulations of manufacturing environments, allowing for virtual prototyping and worker training without the risks or costs associated with physical trials.

The Agility of Flexible Manufacturing Systems

Flexible Manufacturing Systems (FMS) represent a significant leap towards achieving agility and adaptability in production processes. These systems are designed to quickly adjust to changes in product type and volume, supported by automated control systems and modular equipment. The flexibility inherent in these systems allows manufacturers to respond swiftly to market changes and customer demands without compromising efficiency or incurring significant costs. This agility is a competitive advantage in today’s fast-paced and unpredictable market landscape.

Cybersecurity in the Manufacturing Domain

As manufacturing becomes increasingly digitized, the importance of cybersecurity cannot be overstated. The integration of IoT devices, cloud platforms, and data analytics into manufacturing processes opens up new vulnerabilities that can be exploited by cyber threats. Protecting sensitive data, intellectual property, and critical infrastructure from these threats is paramount. The adoption of robust cybersecurity measures, including encryption, access controls, and continuous monitoring, is essential to safeguard the digital backbone of modern manufacturing.

Conclusion

The future of manufacturing is being shaped by these cutting-edge solutions, each playing a pivotal role in transforming the industry. From the digital integration of Industry 4.0 to the sustainable practices that are becoming a hallmark of responsible production, the landscape is evolving at an unprecedented pace. The adoption of these innovations is not without challenges, including the need for skilled labor, significant investment, and a culture that embraces change. However, the potential benefits in terms of efficiency, customization, sustainability, and competitiveness are immense.