Anyone who has ever worked in the manufacturing industry knows how important it is to have reliable tools that can help with the production process. The Computer Numerical Control or CNC machines have been used in many different industries for a while. This type of machining is great for replacing the manually operated machines and with that improve the production time, performance, and providing better quality products.

Everything that is connected to engineering or design requires some type of CNC machine, and businesses from all around the world have been using these units. One fun fact is that the device you are reading this article on has at least one component that has been made by a computer numerical control unit. In this article, we are going to tell you more about the ways this type of machining benefits your business, and why you should incorporate these units in your production process.

1. Save money

As you probably know, to create the best product on the market, you need to first make a few prototypes. These items can be expensive to create, and the only reason why they exist is so you know if your product is faulty if there are things that can be improved, and to check how it works.

When you use CNC machines, they eliminate the need for a prototype. This machinery can create flawless things and is capable of doing things that no designer or electrical engineer can do. Even though humans make this equipment, when we use it, we eliminate human error.

These units will give you a digital copy of the product as well as the machine, so if you want to check or test things out, you can do it right on the spot. The production time will be faster, and you will save money on expensive prototypes.

2. Better quality

When we use human labor, no matter how great people are at finishing their tasks, they will get tired in time. People need to take breaks, and if they get distracted, the quality of the product will decrease.

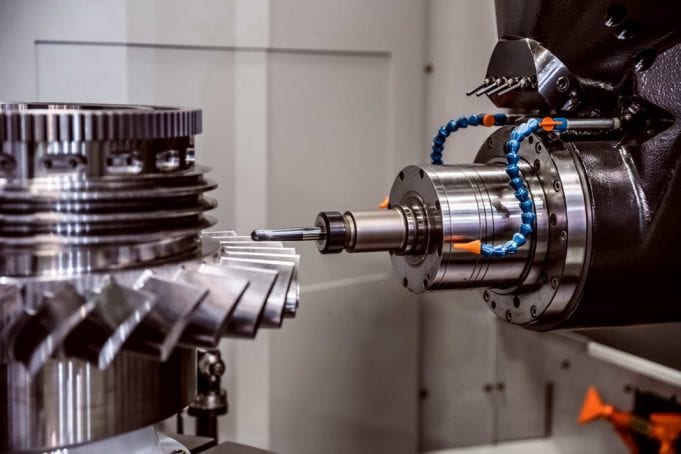

With the use of computer numerical control units, you will increase the overall quality of the items you create in your business. These machines increase not only the accuracy but also the consistency of the components they build.

The automation process will ensure that every part of the product will be the same, there won’t be any minor mistakes, and there won’t be faulty products. With this, you can have your employees focus on the design and to find ways to improve the products. You will also create a safer work environment because the equipment cannot get hurt or injured if anything falls down.

3. Broader spectrum

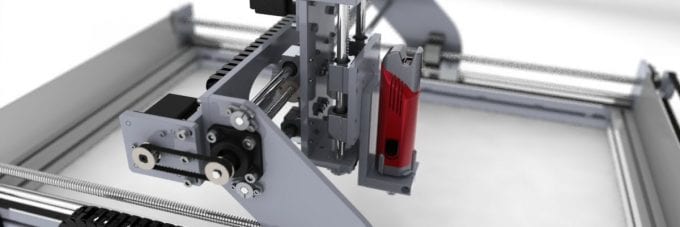

One of the biggest benefits of these units is that you can create products and components you didn’t even think is possible. There are so many different types of machines, so the only thing you need is a designer that will help you draw and plan the item you can build.

For example, if you want a unit that will be able to engrave something in different materials, including wood, acrylic, and even glass and marble, elephant-cnc.com suggests that you should use a CNC router machine.

The Milling units are used to drill and cut the material, and the Lathe ones rotate the materials and with that, they can operate on different sized parts. The Electric Discharge machines are used to change the size and the shape of the products and they can be even used in the surface finishing industry.

4. Production process

Every CNC machining company wants to find a way to not only satisfy their customers by creating better items, but also create them faster, and if possible, cheaper.

If your business supplies a lot of users, then you need to make sure that every product you create will be done and delivered on time and without any issues. With the use of the CNC machines, you will be able to create as many products as you want, and there won’t ever be any delays.

The fact that one machine can replace a lot of employees, you will be able to save a lot of costs for the production process. This does not mean that people will lose their jobs, it just means that human workers can focus on more important tasks that require skills and creativity.

The fact that these units provide high accuracy, speed, and precision means that the costs for different things will be cut. They can be on every day of the week, 24 hours per day, throughout the whole year. No matter if it is a holiday or any other special day, the equipment will stay on, without you having to pay a higher hourly rate.

Conclusion

With the use of computer numerical control units, you will ensure the safety of all of your workers, you will provide a better working environment and create an overall safer workplace. Your employees will not be tired, they won’t have to worry about not making a mistake, and when you are not focused, the production process will not suffer.

The CNC machines can produce complex textures and shapes with ease, and with that, you can satisfy even the most demanding customers. When you combine the latest digital software with the right unit, you can create masterpieces with ease.

The price of the machining depends on the type of unit you want to purchase, size, and model. As we already mentioned, there are a lot of different models, so make sure you get the right one for your needs. There are a lot of features these machines offer, so you should try and learn all the things you can do with them.

In case you are not sure what you should purchase, you can always contact the sellers, and talk to them about the different types of machines they are offering. If you want to purchase a lot of them, you can even ask for a special offer or discount. Don’t forget to check and see what the right type of maintenance is and how you can ensure that your unit will work for many years without breaking.